APPLICATIONS

Uses of our products:

• Renewable energy panel structure.

• Drinking water supply.

• Waste collection pipes.

• Electric power stations and mini power stations.

• Piles.

• Column formwork.

• Fluids pipes.

• Borehole and drilling for water.

• Other industrial uses.

PRODUCTS

Products

Our product range is the following:

• Pipe welded longitudinal and circumferential from 8 to 120 inches

(180 – 3000 mm diameter) and thickness between 3 and 25 mm.

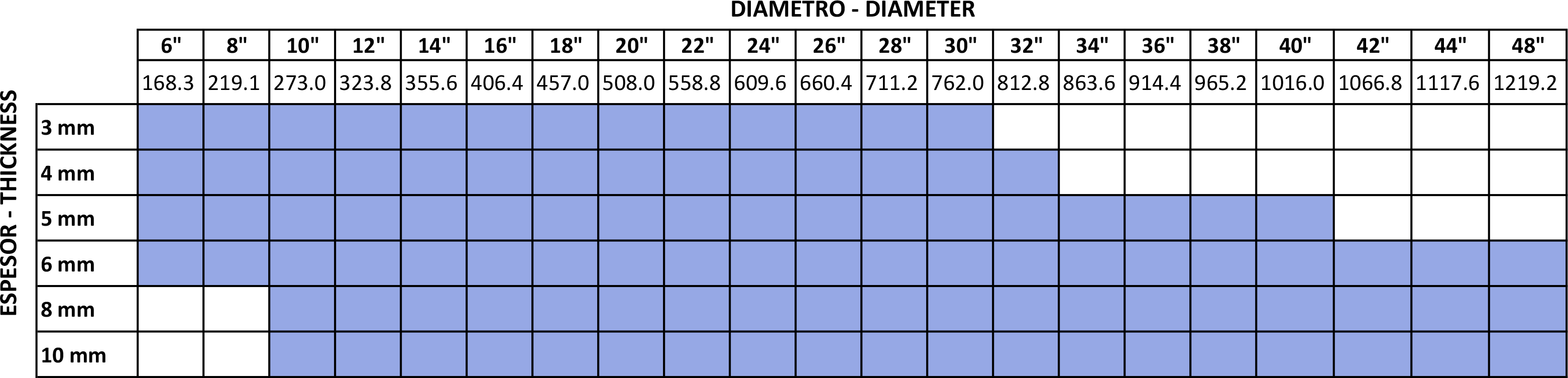

• Helically welded steel pipes between 6 and 48 inches

(160 – 1200 mm diameter) with the possibility of any intermediate diameter. Thickness may vary between 3 and 12 mm.

• Bridge slotted pipe.

• Pipe with perforated sheet.

• Pipe (bridle connection).

• Stainless steel pipes welded longitudinal and circumferential.

We manufacture a wide range of diameters and thicknesses.

We carry out internal quality controls on the finished product, thus complying with our manufacturing standards and the certifications that endorse us. We are an accredited company for pipe manufacturing under the EN 1090 standard (CE Marking).

COMPANY

More than 100 years of history

TASZ is a leading company in Spain dedicated to the manufacturing of large-diameter pipes with helical welding and welded joints, with over 50 years of experience in the pipe sector and more than 100 years in the steel industry.

Both the offices and the manufacturing plant are located in Salamanca, covering approximately 8,000 square meters.

We have a large professional technical team, all certified and with extensive experience in pipe manufacturing.

We manufacture according to the DIN 1615 standard and comply with dimensional tolerances according to EN 10219-2, EN 10217, and EN 10224 standards.

We ensure traceability from the purchase of raw materials to the shipment of the finished product.

We comply with the international quality standard ISO 9001:2015 and environmental standard ISO 14001:2015.

We are a certified company for pipe manufacturing under the UNE-EN 1090 standard (CE Marking).

Possibility of treatment or coating both on the inside and outside of the pipe.

We have our own truck to facilitate material delivery.

In recent years, we have worked on international projects in the thermo-solar field together with the most recognized companies and engineering firms worldwide in this sector, manufacturing both in Spain and on-site in the countries where the projects are executed.

HISTORY

In 1915, Andrés Santiago Álvarez created in Salamanca a company dedicated to the steel warehouse and the manufacture of agricultural tools, bars and horseshoes.

After a few years and to the death of the founder in 1941, his children take charge of the company and it is denominated Viuda de Andrés Santiago.

In 1962, the company becomes Hierros Andrés Santiago Zarzuelo. It continues with the management of steel warehouse, incorporates the sale of cold rolled pipe, profiles and especially in the distribution of sheet steel.

In 1970, it began its production of pipes with longitudinal and circular welding, and in 1978 it created TASZ (Talleres Agrícolas Santiago Zarzuelo), which continued with the same activity until 1992, when the company took a step forward and start to the manufacture of helically steel pipes, achieving greater breadth in the range of pipes and higher quality in the final product result.

Since then, the procedure has been improved, improving the processes of quality and production, while being accompanied by the most advanced technology.

Today they are the third and fourth generation (Andrés Santiago Mariño and Andrés Santiago González) who run the company (TASZ TUBOS Y ACEROS, S.L.) giving a change to the business and focusing the future on international projects. They are active with 7 helical machines and 4 rollers that allows them to adapt to the current market and give a fast and quality service.